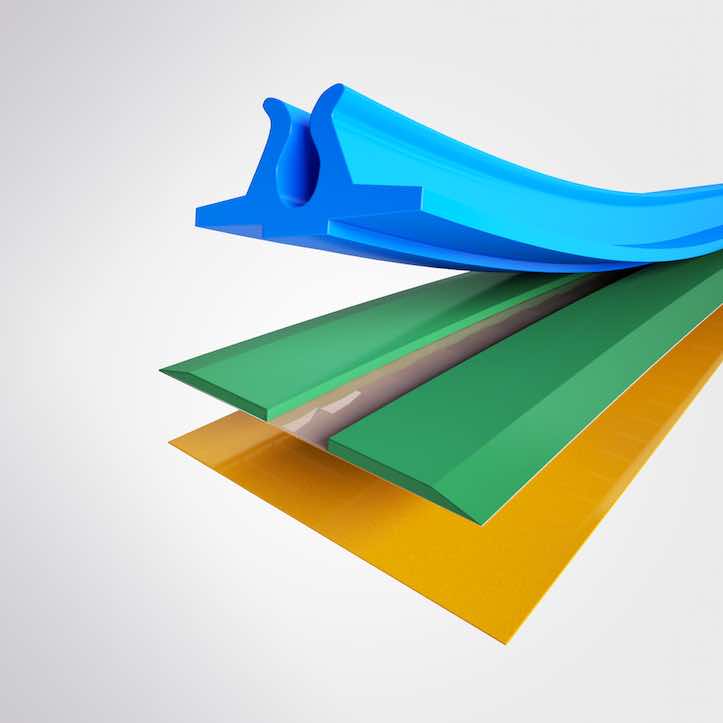

C&T Channel Matrix (C&T), the world's leading manufacturer of creasing matrix and ejection rubber for the corrugated industry, has noticed a trend to move towards lightweight and recycled corrugated and packaging liners, as the packaging industry strives to reduce the weight of packaging and save on raw materials. This can give advantages in terms of cost and sustainability, but there can also be technical issues with light-weighting leading to problems and downtime in production.

Sidebar

Consumables

New box testing equipment at Antalis’ smart packaging centre

The new equipment will help Antalis’ Smart Packaging Centre (SPC) to design packaging with better performance values and, ultimately, less material.

Antalis Packaging has added a burst test machine and two new corrugate-testing machines at its Leicestershire-based SPC to help customers to further evaluate current or new packaging solutions.

Colored By INX Can Design Contest April 29 deadline nears

The clock is winding down on the entry deadline for this year’s Colored by INX Can Design Contest. Open to all brand owners, metal decorators, design agencies and marketers who used the INX Color Catalog to produce a commercial can design before January 1, 2024, all entries with the submission form, electronic design, and actual printed can must be postmarked no later than April 29.

LeadEdge Flexo celebrates 15th anniversary with growth success

LeadEdge Flexo (‘LeadEdge’), a renowned innovator in the corrugated and flexographic printing markets, is celebrating both its fifteenth year in business and its most successful growth period since its inception, recording 40% business growth over the past three years.

Toyo Ink India to Boost Adhesive Production Capacity by 3.5X

Aiming for top share of solvent-based adhesives in Indian market by 2026

Flint Group to spotlight the future of Flexographic inks and coatings at the FTA INFOFLEX 2024

Flint Group, a leading name in ink and coating solutions for the printing and packaging sectors, announces its participation in the Flexographic Technical Association’s (FTA) INFOFLEX 2024. The premier event for the North American flexographic industry takes place May 6 & 7 in Kansas City, Missouri.

IST METZ at drupa 2024 – more than UV Innovative thinking and modern aesthetics

After a long break, the time has come again: drupa will take place in Düsseldorf from May 28 to June 7. UV system manufacturer IST METZ from Nürtingen, will celebrate a special milestone in the company's more than 45-year history this year.

ACTEGA Asks ‘Meet Us Where You Need Us’ at Drupa 2024 – Bringing Latest Products, Sustainable Innovation and Regulatory Expertise to Locations Across the Show

ACTEGA, manufacturer of specialty coatings, inks, adhesives and sealing compounds for the print and packaging industry, has announced its participation in drupa (28 May – 7 June 2024, Dusseldorf, Germany). ACTEGA experts will be based at various touchpoints across the show to present the company’s extensive range of product and technology solutions developed for printers and converters seeking more sustainable solutions and high-value embellishment options.

INX Color Catalog update provides more options for Craft Brewers Conference audience

INX International’s status as North America’s leading supplier of metal decorating ink for the 2-piece metal can market continues to grow ahead of the Craft Brewers Conference and BrewExpo America, being held April 21-24 in Las Vegas at the Venetian Convention & Expo Center.

Adestor by Lecta partners with RecyClass to drive circularity in labelling

Adestor by Lecta, Lecta’s self-adhesive material branch, is proud to announce its platinum partnership with RecyClass, a key European initiative promoting plastic recyclability. This partnership reflects Adestor's ongoing commitment to minimizing environmental impact and accelerating the transition towards a

circular economy within the labelling industry.

Metsä Board will not invest in a new Kaskinen folding boxboard mill

Metsä Board announced on 15 September 2022 that it will start pre-engineering for a new folding boxboard mill in Kaskinen, Finland. The pre-engineering phase included technical design, design of infrastructure and logistics solutions, tendering for the main equipment as well as financial analysis of the project. The pre-engineering also included an environmental impact assessment and an application for an environmental permit.