Bio-based coatings are eco-friendly alternatives to petrochemical based coatings which are derived from renewables or agricultural biomass, such as oil seeds, lignin, lipids, proteins, starch, polysaccharides, polyesters, and cashew nutshell liquid.

Sidebar

Knowledge base

Improving Transparency and Traceability within Supply Chain First Mile

By Lee Metters, Global Business Development Director, Domino Printing Sciences

Typically, when organisations speak of supply chain transparency, they focus on the last mile: the product journey from “production to fork”, with a view to reducing energy and waste while optimising efficiency and flexibility in final delivery. However, the first mile of the supply chain – from “farm to production” – is just as important.

Efficient, Connected, Transparent: Automated Warehousing in Modern Supply Chains

· Toby Odlin, Head of Group Logistics and Supply Chain Projects, Domino Printing Sciences

· Andreas Olsson, Global Sector Manager – Logistics and Distribution, Domino Printing Sciences

· Paul Stinson, Sales Director, Lake Image Systems

Today’s supply chain and warehouse managers are navigating numerous challenges that stem from a combination of global disruptions and shifting market demands.

Antalis Packaging publishes the first edition of ‘The Big Book of Packaging’

Antalis Packaging has published the first edition of ‘The Big Book of Packaging’, an essential resource showcasing the latest advancements in packaging materials, machinery, and sustainable solutions. Designed to support businesses across the UK and Ireland, this new publication highlights how Antalis continues to lead the way in all things packaging.

Weaving the physical and digital into connected packaging

Bridging the physical and digital worlds, industry leaders explore how connected packaging can drive accessibility, sustainability, and consumer trust in an AI-powered era.

Understanding the consumer: How luxury brands use psychology and packaging to entice consumers

Professor Ben Voyer explains how the luxury market is utilising packaging to tap into the consumer psychology and initiate purchasing decisions.

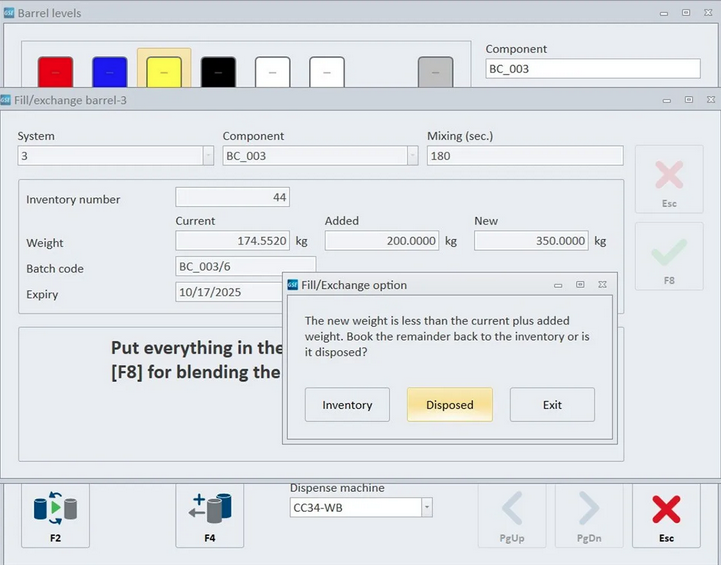

Managing ink waste: meeting GFSI standards for safe disposal

Continuing our series on navigating ink-related food safety standards

We’ve started a blog series that focuses on meeting the requirements of the Global Food Safety Initiative (GFSI). In our first post, we introduced the three main food safety management schemes for packaging printers and summarized eleven food safety standards related to ink.

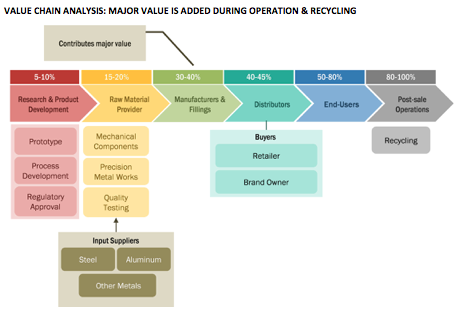

Metal Packaging Market

The packaging segment is projected to record a CAGR of 5.8% during the forecast period. The packaging industry utilizes significant quantities of metals particularly aluminum and steel, which are among the most extensively recycled materials worldwide. The metal packaging Industry is prominent because of its crucial role in reducing waste.

Hot Melt Adhesives - an overview

Hot-melt adhesives are solvent-free thermoplastic adhesives that are commonly available in the form of pellets and solid cylindrical sticks of various diameters. These adhesives have Spread ability irrespective of the surface texture; they cool down rapidly at room temperature. They are 100% thermoplastic solids at temperatures below 80'C (176 • F). However, they are applied in a molten state at temperatures ranging from 120 •C to 180•C (248—356• F), depending on the application and materials to be bonded.

QR Codes Powered by GS1: Empowering Brands with Essential Data for Downstream Visibility

Nigel Allen, Marketing Manager 2D Codes, Domino Printing Sciences, explains why it’s time to say goodbye to linear barcodes and embrace enhanced variable data capabilities from QR codes powered by GS1.

Enhanced capabilities

Linear or ‘one-dimensional’ barcodes have been the mainstay on retail and product packaging since the 1970s. However, they are slowly but surely being replaced by a newer technology: the two-dimensional barcode, or ‘2D code’, which can offer significant benefits to brands while still being used at the retail point of sale (POS).

Adhesive vs. Extrusion Lamination – What’s the Difference and Why Does it Matter?

By Haley Schrauben, Product Manager, Oliver Healthcare Packaging

Film and foil laminations used for pouching applications across the healthcare packaging industry serve a vital purpose in protecting single use medical device, diagnostic, and pharmaceutical products.