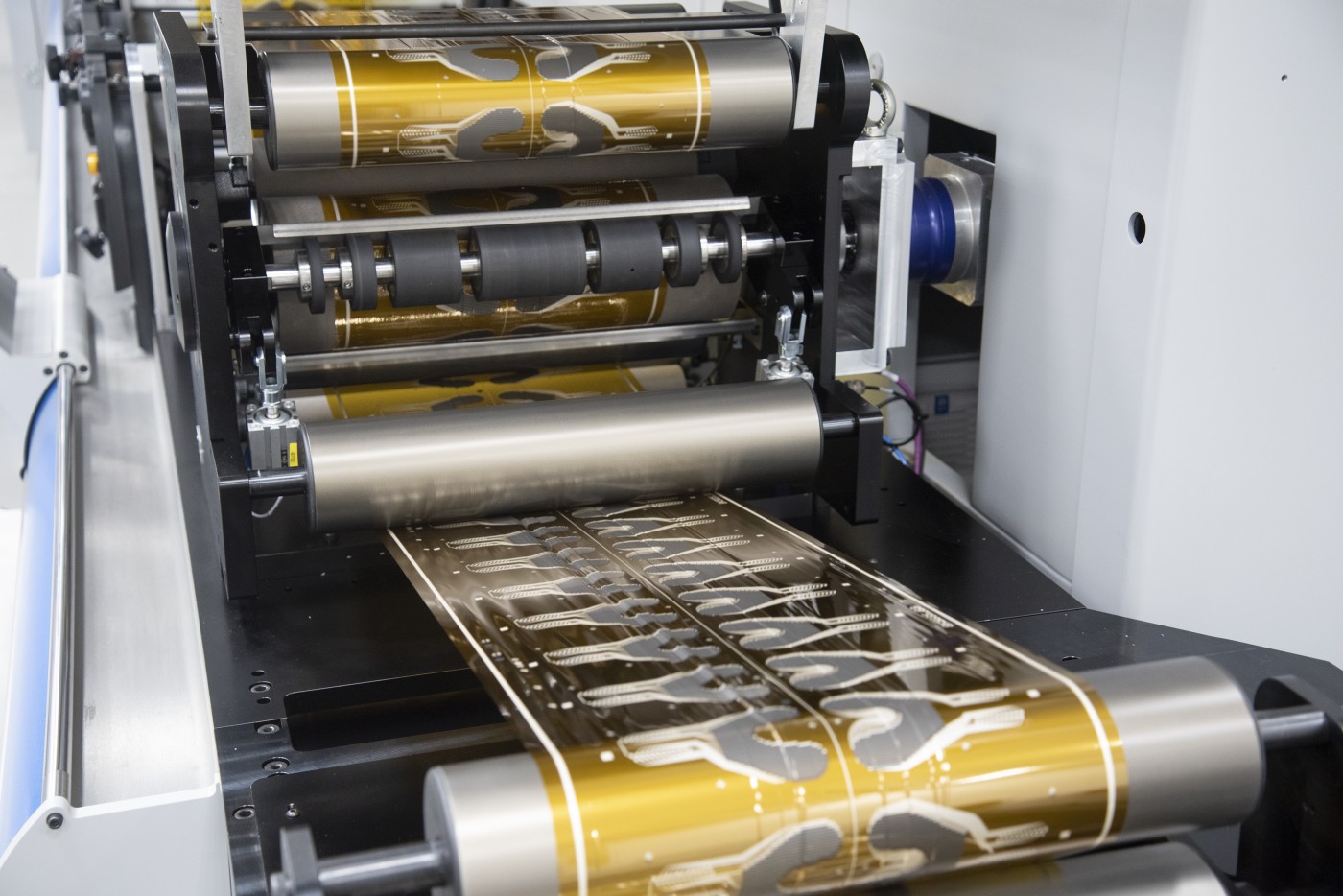

Heidelberger Druckmaschinen AG (Heidelberg) has set up a dedicated business unit for the industrial development, manufacture, and sale of printed and organic electronics. The company has also started production at its Wiesloch-Walldorf site, investing some five million euros in a complete production line for printed sensors. Sensors developed at InnovationLab (iL) in Heidelberg for use in dental technology are set to be printed first. These innovative printed sensors make it possible, for the first time ever, to digitally record the distribution of masticatory pressure during occlusion, that is to say when the upper and lower jaws come together. 3D visualization on a tablet and data archiving enable malocclusions to be identified and subsequently corrected. Looking further ahead, Heidelberg is to use state-of-the-art printing technology at its high-tech campus to produce sensors for other digital applications – in particular in healthcare and logistics, and also in the retail and automotive sectors.

Sidebar

Analogue Printing

Zero-fault packaging – myth or reality?

Quality is one of the biggest differentiators in the packaging industry. Other factors matter too of course – cost efficiency, sustainability, lead times – but ultimately if packaging fails the quality test, it can jeopardize a whole run, and a customer relationship with it. In some sectors – pharmaceuticals for example – packaging faults can have even more significant consequences.

Koenig & Bauer celebrates award series at virtual printing fair

New Rapida generation receives both iF Design Award and Red Dot Design Award

Sheetfed offset flagship combines technical and visual highlights

German Brand Award for consistent brand management

BOBST helps converters enter new markets with shrink sleeve labels production

As one of the fastest growing segments in the label market, shrink sleeves represent the third most important label format after pressure-sensitive and wet-glue labels. According to Smithers, the global market share of all types of sleeve labels will grow annually by 6.9% in the period 2019–24, making it the highest growth type among all label formats.

Edale launches new Flexographic Label press

Affordable Highly Productive Cost-Efficient Quality Label Printing

Leading British designer and manufacturer of printing and converting machinery, Edale Ltd has launched its latest new addition to its FL range of flexographic presses.

Contiweb introduces a new digital platform for analysis and control of print production.

Contiweb, a specialist in advanced printing, drying and web handling technologies, today announced the launch of MyContiweb, a new digital platform that gives printers the insight and control they need to increase production to optimum efficiency.

Sustainability in packaging printing

The VARIOMAN machines and environmental protection go together like ink on paper.

Sustainability is the future. Only a few years ago far too few printing companies were committed to environmental protection. Now manroland Goss is conquering the future of the printing industry with the convincing concept of the VARIOMAN.

BOBST recognizes internal process innovation with first ever Inventor Award

BOBST has awarded one of its employees a prestigious award today in recognition of a groundbreaking invention that he pioneered within the company.

Introducing BOBST AlOx GEN II

The next generation clear barrier process for sustainable flexible packaging materials

Bobst: Get connected and adapt to the COVID-19 crisis with Helpline Plus remote assistance

The unfolding COVID-19 pandemic is impacting every aspect of society and business. To protect health and livelihoods, much activity has been paused, but shutting shop isn’t an option for many manufacturers – food and pharma packaging converters, for instance. For these key industries, keeping machines running without in-person maintenance operations is crucial, and the answer is to get connected with remote assistance.

An insight into the BOBST industry vision

Digitalize, automate and connect: the backbone of packaging production

The packaging business community is dealing with the unprecedented Coronavirus (COVID-19) situation with both urgency and a deep sense of care. It will come to an end. With many people working from home, we want to provide content about the equipment, systems and processes that we were due to showcase in the coming months, letting you know what is new and expected so that you can plan ahead for your own business.