Flexographic printing technology uses plates made of flexible materials such as plastics, rubbers, and UV-sensitive polymers for printing. This technology is widely used for package printing due to various benefits, such as high-quality printed images and high production speed.

It can print on corrugated containers, folding cartons, labels and tags, paper sacks, and plastic bags. The key offerings in this market include flexographic printing machines and flexographic printing inks. The packaging industry, driven by increasing consumer demand for packaged goods, has contributed significantly to the demand for flexographic printing. Flexographic printing is widely used on packaging materials such as labels, cartons, bags, and flexible packaging. The packaging industry is continually evolving with the booming e-commerce industry and rising trends of online shopping. Thus, there has been a surge in demand for packaging materials to protect products. According to MarketsandMarkets The global Flexographic Printing Market is poised to reach $10.6 billion by 2028

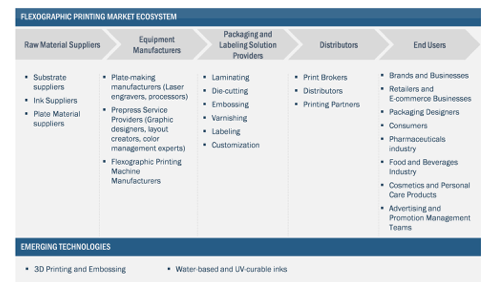

FLEXOGRAPHIC PRINTING MARKET: ECOSYSTEM MAPPING

A few of the top companies providing flexographic printing in the ecosystem are BOBST (Switzerland), Mark Andy Inc. (US), Amcor PLC (Australia), Windmoller and Holscher (Germany), and Koenig & Bauer AG (Germany). The flexographic printing market is highly fragmented. It is marked by the presence of a few tier 1 companies, including BOBST (Switzerland), Mark Andy Inc. (US), as well as numerous small and medium-sized enterprises such as Uteco (Italy), Gaullus (Switzerland), TRESU (Denmark), OMET (Italy), Star Flex International (India). These companies mainly offer various flexographic printing press services and products. These products and services are widely used in the food and beverages and pharmaceuticals industries, Retailers and e-commerce businesses, cosmetics and personal care products, and consumers. 3D printing and embossing are innovative technologies integrated into the flexographic printing process to enhance printed materials' visual and tactile aspects. These technologies add depth, texture, and unique effects to packaging, labels, and other printed products. 3D printing and embossing create visual depth and intricate textures that elevate the overall appearance of printed materials. This effect enhances the visual appeal of packaging and labels, making them more attention-grabbing on the shelf. Embossed textures generated through these technologies provide a tactile experience for consumers.

Flexographic printing can integrate 3D printing and embossing to create customized packaging solutions in which brands can tailor packaging designs to specific events, promotions, or individual customer preferences. 3D printing and embossing enable the creation of limited-edition packaging and labels that appeal to collectors and consumers looking for exclusive products. It is also used to create realistic prototypes and mockups of packaging designs. Water-based and UV-curable inks are considered more environmentally friendly alternatives to solvent-based inks. Water-based inks have lower volatile organic compounds (VOCs) levels, reducing air emissions and potential health risks. UV-curable inks contain little to no solvents and release fewer harmful environmental emissions. Using water-based and UV-curable inks helps flexographic printers decrease their carbon footprint and contributes to a cleaner and healthier printing process. UV-curable inks dry almost instantly when exposed to UV light, allowing for faster production speeds and reduced drying-related delays. Similarly, water-based inks also dry relatively quickly, contributing to improved efficiency. Water-based and UV-curable inks bond quickly to various substrates, ensuring good adhesion and durability on various materials.

Flexographic printing is used in various industries and applications due to its versatility, efficiency, and cost-effectiveness. Flexographic printing is particularly well-suited for large-volume printing of packaging materials and other products. It is extensively used in the packaging industry for printing on various packaging materials, including flexible films, laminates, paperboard, and corrugated cardboard. It is used to print attractive designs, product information, branding, and nutritional facts on these packages. Flexographic printing is widely used for producing labels of all types, including product labels, barcode labels, RFID labels, and more. It is commonly used in the food & beverage, pharmaceutical, electronics, and logistics industries. Based on application, the flexographic printing market has been segmented into corrugated packaging, flexible packaging, cartons, labels and tags, and others (bags and sacks, newspapers, envelopes, and sanitary/kitchenware). In recent years, environmental consciousness has become a significant concern for businesses. The shift towards water-based and UV-curable inks with the use of fewer solvents leading to lower volatile organic compound (VOC) emissions combined with the usage of less ink and striving for less additives within ink, has reduced the environmental impact of flexo printing.