Innovative technology for anilox rollers offers printers significant benefits in terms of quality and performance

Sidebar

Consumables

Sun Chemical to Showcase Advanced UV-LED Inks at BOBST Competence Centre Grand Opening in Italy

Sun Chemical is proud to announce its partnership with BOBST, at the grand opening of BOBST’s new Competence Centre in Firenze, Italy from 8th -10th October, 2024.

Stora Enso announces opening of Production Unit for Dry Molded Fiber

PulPac licensee, Stora Enso, announces the opening of a groundbreaking Dry Molded Fiber Production Unit in Skene, Sweden. The facility is the largest and most advanced of its kind, marking a significant milestone in sustainable packaging technology. Production is set to begin in Q4 2024 after successful large-scale testing.

Excelitas Technologies Introduces New Generation Phoseon UV LED Curing Systems for Fiber and Wire Coatings

New three-part reflector design improves irradiance by 20% at the fiber

Innovia extends ISCC PLUS certification to their Polish production hub

• Extended certification to their production hub in Plock, Poland

• Portfolio reflects growing demand for sustainable solutions

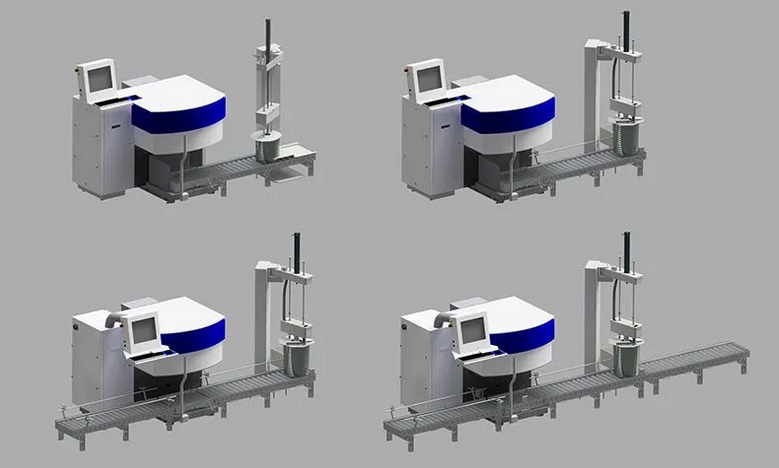

GSE’s new conveyor streamlines ink handling in corrugated and flexible packaging workflows

New system provides an automated, single-pass solution for ink dispensing, blending and container labelling, improving ergonomics and efficiency in the ink kitchen.

GSE presents sustainable ink dispensing solutions at Taiwan’s TIGAX 2024 show

GSE to showcase its Colorsat automated ink dispensers – helping package printers assure repeatable colour and comply with Taiwan’s strict emissions-reduction regulations. The company presents its solutions at the booth of its agent Foremost eMage at TIGAX, marking GSE’s first presence at a Taiwan print trade fair.

Pulse brings the magic of Monolox to life at workshop hosted by Mark Andy Poland

The event in Warsaw showed the real and tangible benefits of the innovative fixed anilox printing system to printers from across Europe

High-impact paper-based solutions for the beverage industry

Sappi exhibits at BrauBeviale in Nuremberg for the very first time

mjet|1 from Marbach Die Supplies: Waterjet cutting machine for maximum efficiency in diemaking

In addition to materials, Marbach Die Supplies also supplies high-quality machines for the production of cutting-dies. One machine that significantly increases efficiency in diemaking is the mjet|1. This compact waterjet machine cuts ejector rubbers automatically and with the highest precision.

Valmet to supply an OptiConcept M board making line to Anhui Linping Circular Development in China

Valmet is to supply an OptiConcept M board making line with automation and services to Anhui Linping Circular Development in China. The new board line PM 8 will produce recycled liner grades. The start-up is scheduled for the end of 2025.