The globally operating diemaker Marbach is known on the market for its innovative solutions for packaging production. In the corrugated board sector, one of the latest Marbach technologies is the DZL|plateXL, a zone levelling solution for large format die-cutting machines. This ensures significantly reduced make-ready times.

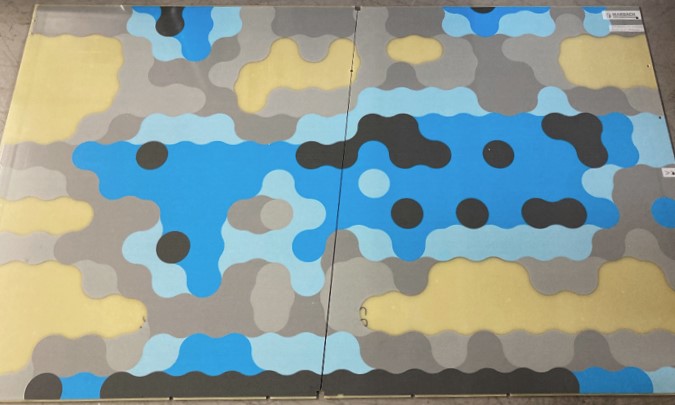

Unevenness in the cutting platen is often caused by wear and tear on the machine. This is a common problem in packaging production, which affects the processing speed as well as the quality of the blanks. Ralf Nuyken, industry manager at Marbach, explains: "The DZL|plateXL has been specially developed for large format corrugated die-cutting machines. It consists of a two-part protection plate that is individually adapted to the height profiles of the respective die-cutting machine. Once inserted, the DZL|plateXL ensures permanent and efficient zone levelling. This compensates height differences in the cutting platen, resulting in optimum pressure conditions during die-cutting and significantly reduced make-ready times for each job. Productivity in packaging production is increased."

The little brother of the DZL|plateXL is the DZL|plate, which was designed for smaller-format cardboard packaging machines.

www.marbach.com