The VARIOMAN machines and environmental protection go together like ink on paper.

Sustainability is the future. Only a few years ago far too few printing companies were committed to environmental protection. Now manroland Goss is conquering the future of the printing industry with the convincing concept of the VARIOMAN.

Sidebar

Analogue Printing

BOBST recognizes internal process innovation with first ever Inventor Award

BOBST has awarded one of its employees a prestigious award today in recognition of a groundbreaking invention that he pioneered within the company.

Introducing BOBST AlOx GEN II

The next generation clear barrier process for sustainable flexible packaging materials

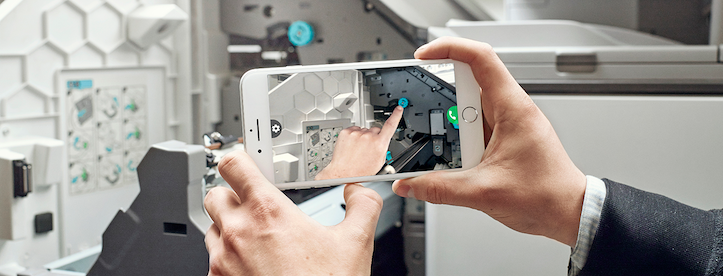

Bobst: Get connected and adapt to the COVID-19 crisis with Helpline Plus remote assistance

The unfolding COVID-19 pandemic is impacting every aspect of society and business. To protect health and livelihoods, much activity has been paused, but shutting shop isn’t an option for many manufacturers – food and pharma packaging converters, for instance. For these key industries, keeping machines running without in-person maintenance operations is crucial, and the answer is to get connected with remote assistance.

An insight into the BOBST industry vision

Digitalize, automate and connect: the backbone of packaging production

The packaging business community is dealing with the unprecedented Coronavirus (COVID-19) situation with both urgency and a deep sense of care. It will come to an end. With many people working from home, we want to provide content about the equipment, systems and processes that we were due to showcase in the coming months, letting you know what is new and expected so that you can plan ahead for your own business.

RedButton as the remote printing consultant – an innovative solution from Schmid Rhyner

Machine downtimes are costly and time-consuming. Depending on the product, printing tests need to be performed before actual production. Currently, the coronavirus or even crises, attacks and other situations in different countries do not always allow application engineers to travel to customers. Schmid Rhyner's support solution, unique for the printing industry, also supports customers in this situation. RedButton is the name of the new innovative online support solution.

RMGT to Host ELITE RMGT User Group Meeting in Las Vegas at Print UV Conference

RMGT, the leader in providing LED-UV curing technology for sheet-fed offset presses announces that the ELITE RMGT Users Group will meet at the Trump International Hotel on March 25, 2020 in Las Vegas, Nevada. This meeting will be held just prior to the opening of the Print UV Conference, at the Encore by Wynn Las Vegas Resort on March 25-27, 2020. RMGT customers across North America will participate in a forum designed to share insights on the impact that LED-UV curing technology can have in the business of offset print. RMGT was the first offset press manufacturer to develop and introduce LED-UV curing technology to the offset press market. 2020 marks the 12-year anniversary of this notable accomplishment.

Contiweb Launches New Fluid Applicator to Advance Digital Print Quality

Contiweb, a specialist in state-of-the-art technologies for printing, advanced drying and web-handling, announces today the launch of its Digital Fluid Applicator (DFA), a standalone remoistening applicator for digital web presses, developed to significantly improve the quality of digitally printed products.

RMGT & GEW LED-UV Curing Take Center Stage at Print UV Conference

RMGT, the global pioneer in LED-UV curing systems for sheet-fed offset presses, will partner with GEW (EC) Limited at the 2020 Print UV Conference to be held March 25-27, 2020, at the Encore by Wynn Las Vegas Resort in Las Vegas, NV.

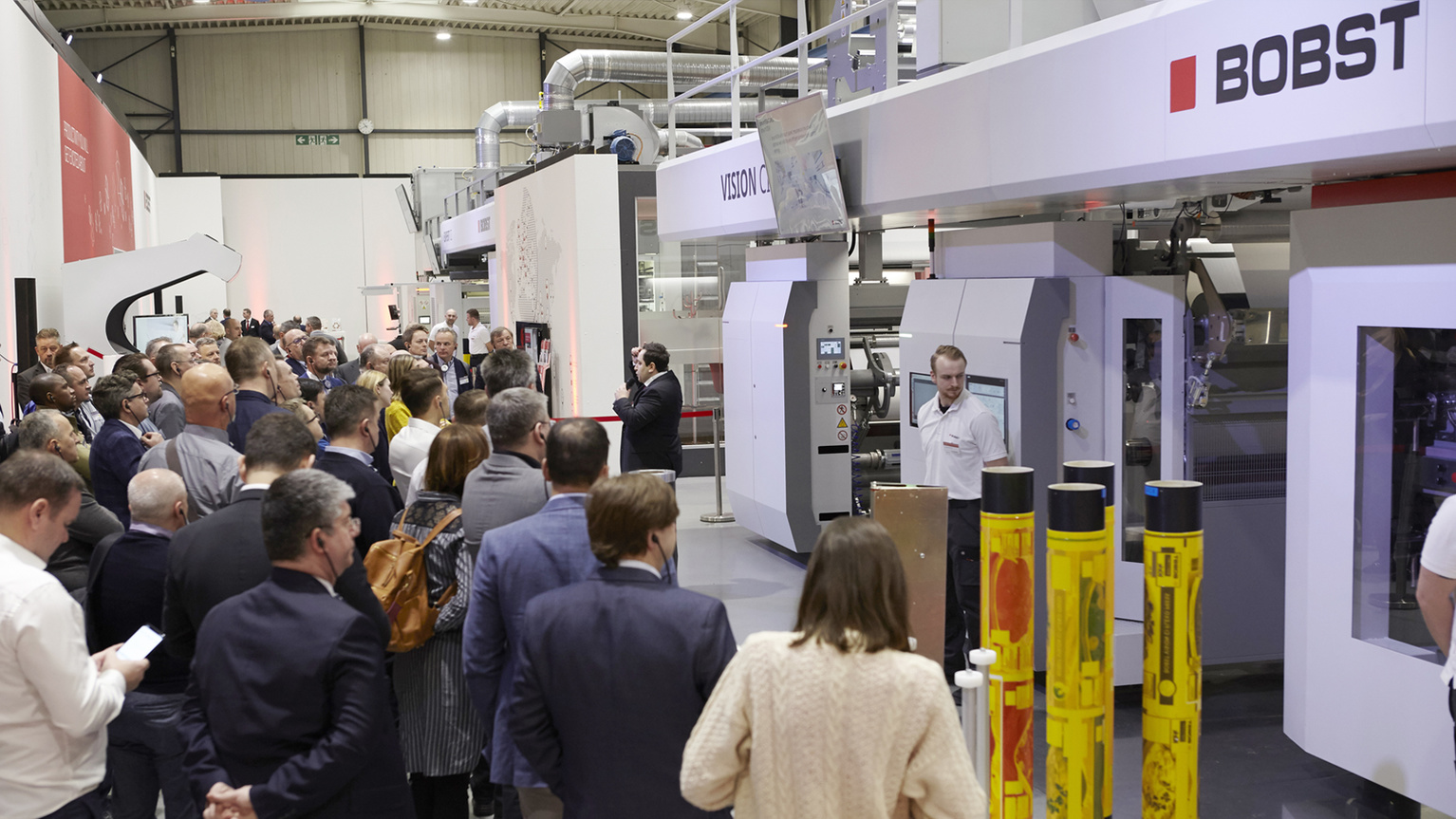

Full end-to-end flexo process experience at Bobst Bielefeld Flexo Center of Excellence Open House

Full end-to-end flexo process experience at Bobst Bielefeld Flexo Center of Excellence Open House

BOBST hosted an Open House at its new Flexo Center of Excellence at Bobst Bielefeld on 13 February 2020, giving attendees the opportunity to experience the entire flexo process from start to finish.

The Competence Center at Bobst Bielefeld’s has been extended to include a pre-press room, meaning it is now a fully comprehensive Center of Excellence for the flexo process, specifically for Extended Color Gamut (ECG) for wide-web CI flexo presses. The Center benefits from an “open-partnership” system, meaning all of BOBST’s valued industry partners are present, ensuring the integration of all the elements that combine to make a flawless end-to-end process.

MPS Systems Asia appoints Müller Korea as local agent in South Korea

Local representation for MPS flexo, hybrid and offset printing solutions in South Korea is now provided by Müller Korea. MPS Systems Asia, with headquarters in Malaysia, made the agreement with Müller Korea in the latter half of 2019.