Custom Solution

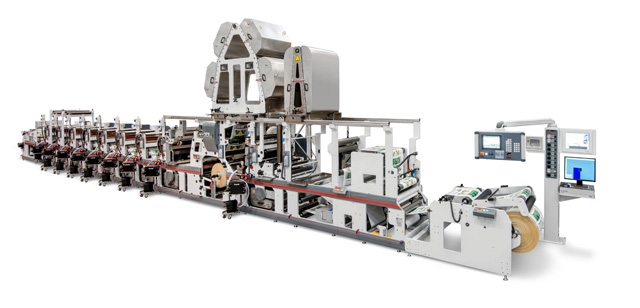

A OMET custom-made packaging printing machine is the modular answer to the needs of companies open to innovation and researching new solutions.

Normally, special custom-made packaging printing machines are created in response to a client’s need to stand out from the competition and obtain an advantage on the market by offering innovative or even unique products.

Thanks to the extensive experience acquired during decades of activity and the great successes enjoyed along the way, OMET has become a reference in the custom-made packaging printing machine manufacturing industry; the perfect partner chosen by many large companies and multinational corporations that wish to stand out from their competitors.

Innovation with passion

Each flexo printing press is special and has its own story, but all OMET packaging printing machines have in common innovation and the passion with which they have been made: new technologies and innovative production processes designed to create new, unique products, increase productivity and quality, and guarantee cost reductions (by reducing waste and downtime).

varyflexV2_b

Multiple competencies

All custom-made machines are developed in close collaboration with clients: on-site assessments and detailed analysis of specific requirements are at the base of the design process and feasibility study of each project. Once the technical and economic feasibility assessment of a project is complete, a multi-competence team – which includes personnel from the Technical Office, the Research & Development, Mechanics and Electronics Departments and a very experienced tester/printer – starts working on the best ad hoc solution for the project at hand.

As all custom-made machines are different, development time – from design to delivery –may vary, depending on the complexity of the project. However, it normally requires between six and twelve months of work.

Collaboration and Confidentiality

When a custom-made flexo printing machine is the result of the combination of OMET’s technology and know-how with the client’s proprietary technology, the synergy between the people and the competencies involved are essential to the success of the project. In such highly personalised projects, confidentiality is a paramount element, as the client’s proprietary technology is often the crucial factor behind the advantage over competitors and therefore an important asset that needs to be protected.

varyflexV2

100 % success

Its problem solving attitude is one of OMET’s strongest qualities and the main reason behind its success in creating flexo printing machines for a variety of different printing and converting sectors. The extensive experience acquired during decades of activity and the company’s constant research for new technologies enables its Development Team to find the best solution for each project: all clients who have commissioned a custom-made press from OMET and have been assured of the feasibility of their project, have always obtained the result they expected and satisfied had their production needs satisfied.

Constant improvement

The experience acquired directly in the field and the new knowledge that comes with each individual project keep increasing OMET’s ability to find effective solutions for the needs of companies across a variety of sectors.

Often, new and unique solutions developed while designing and creating custom-made machines can be applied also to standard modular ones. The new developed technology, when it is not the result of the synergy with a client’s proprietary technology, can be replicated on other machines or can help future projects.

Challenge accepted

OMET’s custom-made machines are unique, highly personalised, designed and conceived to respond to very specific needs thanks to OMET’s competence and experience and its willingness to accept customers’ new challenges.

www.omet.it