Innovating. Always. To be a step forward in the market, and give to its clients a chance to do the same. Following this idea, OMET planned its presence in Labelexpo Europe, aiming once again to surprise with the high technology level, the versatility and the completeness of its portfolio.

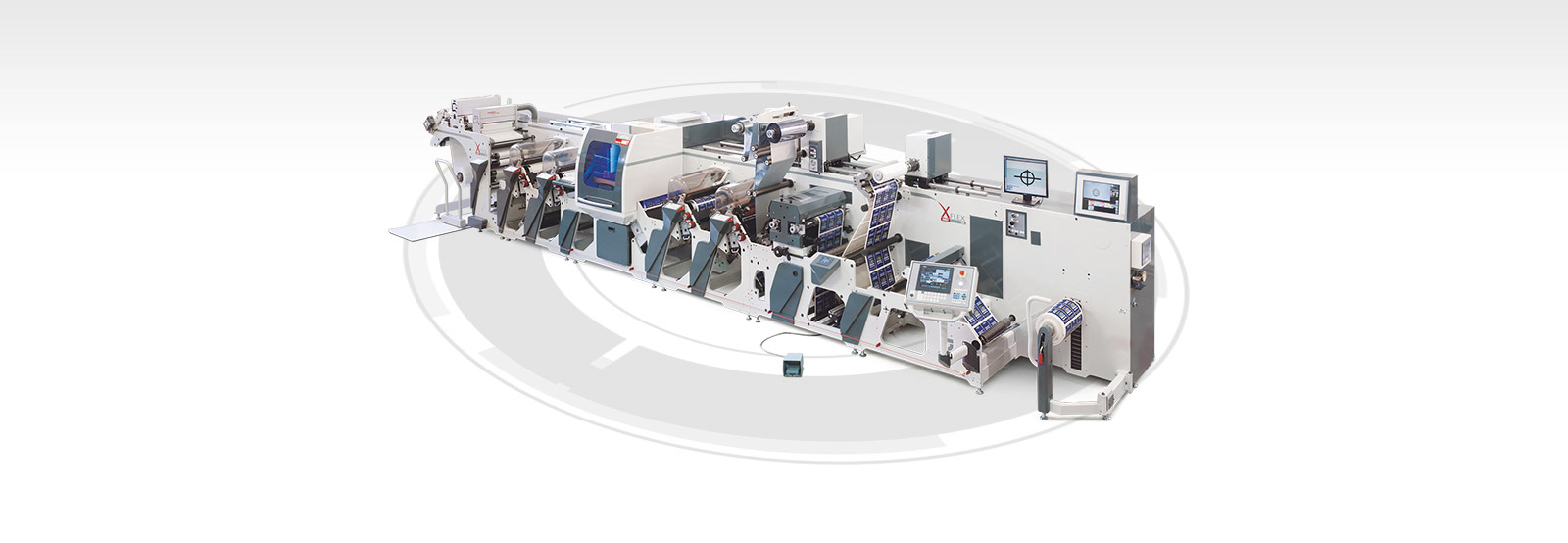

Three presses at the show: XFlex X6.0, iFlex and XFlex X6 Offset, upgraded according to “industry 4.0” drivers, to prove that innovation is the only growth strategy possible now.

Digitalization, interconnection, remote control, high precision diagnostics: these concepts, that are orienting the industrial world, for a long time have been the guidelines of OMET planning, that never stops exploring new bonders of industrial automation.

Labelexpo Europe, the most important exhibition in labels printing world, for years has been the occasion for OMET to bring great innovations to the market, being the theater of a history of innovation and excellence that is going to open a new chapter.

For Labelexpo 2017, OMET has chosen three presses that shares OMET’s extraordinary technology: iFlex, XFlex X6.0 and XFlex X6 Offset.

Top product is certainly XFlex X6.0: it is going to set higher standards in technology and automation by preserving the strong points that made XFlex X6 the best narrow-web platform of the last 10 years.

X6.0 features renewed flexo stations with automatic pressure adjustment and intelligent cruise control, with the capability to automatically set and correct the printing pressure at each job changeover, variation of material or production speed.

OMET developed also a new high-performance system for improved register adjustment and control: Multivision. It consists of a set of smart micro-cameras, one on each flexo unit, which allow for independent color-to-color register setting in real time, without waiting for the printed image to reach the end of the line. This means a few seconds of make-ready time and start-up waste close to zero!

A complete restyling and a new interface will make the press more user-friendly, ergonomic and intuitive, offering the operator a new working experience and the comfort of an automatic independent process.

OMET XFlex X6.0 will be presented with the other innovative proposals in hall 6 at stand C49-C53, where it will be also possible to attend real printing demonstration with quick jobs changeover, thanks to new technologies that make set-up process completely automatic.

People would have the concrete possibility to see OMET technology and complete range of products, which comprises printing press for every need, from smart flexo printing for labels to complex materials, from combination printing to special solutions, totally customized, with personalized design for all kind of support.

BOX – Chill drums for iFlex

iFlex versatility joins the superior technology of X6.0 OMET, revolutionizing the label printing presses concept: it is able to produce all kind of labels with a maximum efficiency, including wraparound and shrink sleeves. It is suitable for short and long runs, allowing to reach maximum printing performances through user-friendly management and execution speed never seen before. It is also the first flexo machine with laser pointer for pre-register and iVision system for instant correction of printing register.

Born in 2015, today it is shown in the new upgraded version with chill rollers that help cool down the substrate and keep the temperature stable, allowing perfect printing results even on filmic materials (thanks to the new Film Asset). iFlex has also a renewed converting section for sheeting station and the evolution of the exclusive matrix stripping unit: Rock’n’Roll Dual Function.

BOX -XFlex X6 Offset (sleeve)

XFlex X6 Offset is aimed to the biggest printers of flexible packaging and high-quality labels, especially for the wine and spirits sector, offering the maximum replicability of printing works, regardless of volumes or type of subjects. This hybrid printing press has been the first combined Flexo+Offset solution with easy change by sleeves At Labelexpo 2017 XFlex X6 Offset is presented in its complete configuration with 430 mm wide web Flexo+Offset combination with inline hot foil and rotary silk-screen unit for high added values printing products on different materials.

BOX – OMET E LABELEXPO: EXCELLENCE AND INNOVATION HISTORY

For many years, Labelexpo has been the main occasion for OMET to reveal his concept of innovation in the label and flexible packaging printing market. In 1995 OMET Multiflex was the first machine to show a real quick-job changeover thanks to the exclusive removable inking cassette, with astonishing printing quality result, giving a boost to flexo printing potentiality.

Many players of this sector still think of the Varyflex launched in 2001 as the best innovation ever seen in Labelexpo: it was the first machine with servo gearless flexo technology in the narrow-web printing market. Such innovative solution guaranteed a perfect printing registration and a consistent reduction of waste, which means high quality products and costs saving. In combination with the first electronic control, it has become in the following years a sort of benchmark for all machine manufacturers. It was a sort of revolution brought by Omet into the new millennium, together with flexo sleeve concept showed for the first time on Varyflex during the same exhibition.

Six years later, during Labelexpo 2007, OMET promoted a new “revolution” with the XFlex: it was the first press with short web path, thanks to the integration of the chill drum with the impression cylinder, allowing for the least start-up waste on a narrow-web flexo press. XFLEX was also the first machine featuring the Vision System able to achieve a perfect printing register, with no manual operations, simply by pressing a button. During the live demonstrations, the visitors looked for the “trick” that allowed to obtain a perfect register of 0,05 mm, independently from the skills of the operator.

The same “trick” was shown in every following exhibition, where OMET continued to bring further innovations, as a sign of constant investment in research and development: the first variable-size rotary die-cutting unit (MonoTwin Cut) and the first flexo-digital inkjet hybrid press (X-jet) in 2009; the first flexo-offset press with automatic sleeve format change (XFlex X6 Offset) in 2013; The first press with pre-registration through laser pointer and iVision system for real-time register adjustment (iFlex) in 2015.

www.omet.it