Leading folding carton producer, Graphic Packaging International (“GPI”), enhances its manufacturing capacity with the introduction of BOBST MASTERFOLD 110 machinery, including an EASYFEEDER/BATCH INVERTER 4 and a CARTONPACK 4 at its Leeds, UK facility.

Sidebar

Gallus Innovation Days 2018: launching a new digital label entry level press

Already on the first day of the "Gallus Innovation Days", almost 300 visitors came to the headquarters of Gallus to St. Gallen to see the innovations of the Swiss manufacturer of label printing machines. This year, Gallus, a member of the Heidelberg Group, continues this success story for the third time in an even larger exhibition area. During the “Gallus Innovation Days 2018”, which take place from 26 – 28 June 2018, Gallus print experts present how digitization will change the label industry and how Gallus is going to support their customers to manage this drastic industrial paradigm shift.

Closure Systems International’s Pro-Lok GL 38mm Closure Provides an Ideal Solution for Probiotic / Carbonated Soft Drinks

Today’s health conscious consumers are no longer just looking for products that quench their thirst. An ever increasing health trend, especially in younger generations, has driven demand for more functional beverages – e.g., kombucha enhanced products. Closure Systems International (CSI) has launched a new closure engineered ideally for cold-filled products, such as probiotic drinks, energy drinks and carbonated soft drinks.

Bobst (Changzhou) Co., Ltd. Grand Opening and inaugural Open House seals its success with the sale of five machines

The new state-of-the-art greenfield facility of Bobst (Changzhou) Co., Ltd. located in the Wujin District of Changzhou city, in the Jiangsu province of China, played host to three days of celebrations and machine demonstrations on 16, 17 and 18 May 2018. The event marked the official opening of BOBST’s new production facility and Competence Center dedicated to web-fed printing and converting technologies for flexible materials.

ESKO SOLUTIONS SUPPORT STREAMLINED OPERATION AT THE ALEXIR PARTNERSHIP

Significant company-wide benefits delivered at UK folding carton manufacturer

Esko’s collaborative project with The Alexir Partnership has enabled the UK operation to achieve cost and time savings while significantly growing turnover.

A triumph: BOBST’s Open House COMPETENCE 18 shows the future of printing and converting is here and now

COMPETENCE 18, this year’s Open House event at BOBST, attracted over 600 visitors, including many of the leading packaging and label manufacturers and converters in the industry. The event, which took place June 5-8, 2018 at the Competence Center of Bobst Mex, Switzerland, promised to show the “Solutions for the challenge of tomorrow,” addressing key trends facing packaging converters, such as the need for shorter runs, greater versatility, e-commerce and constant innovation.

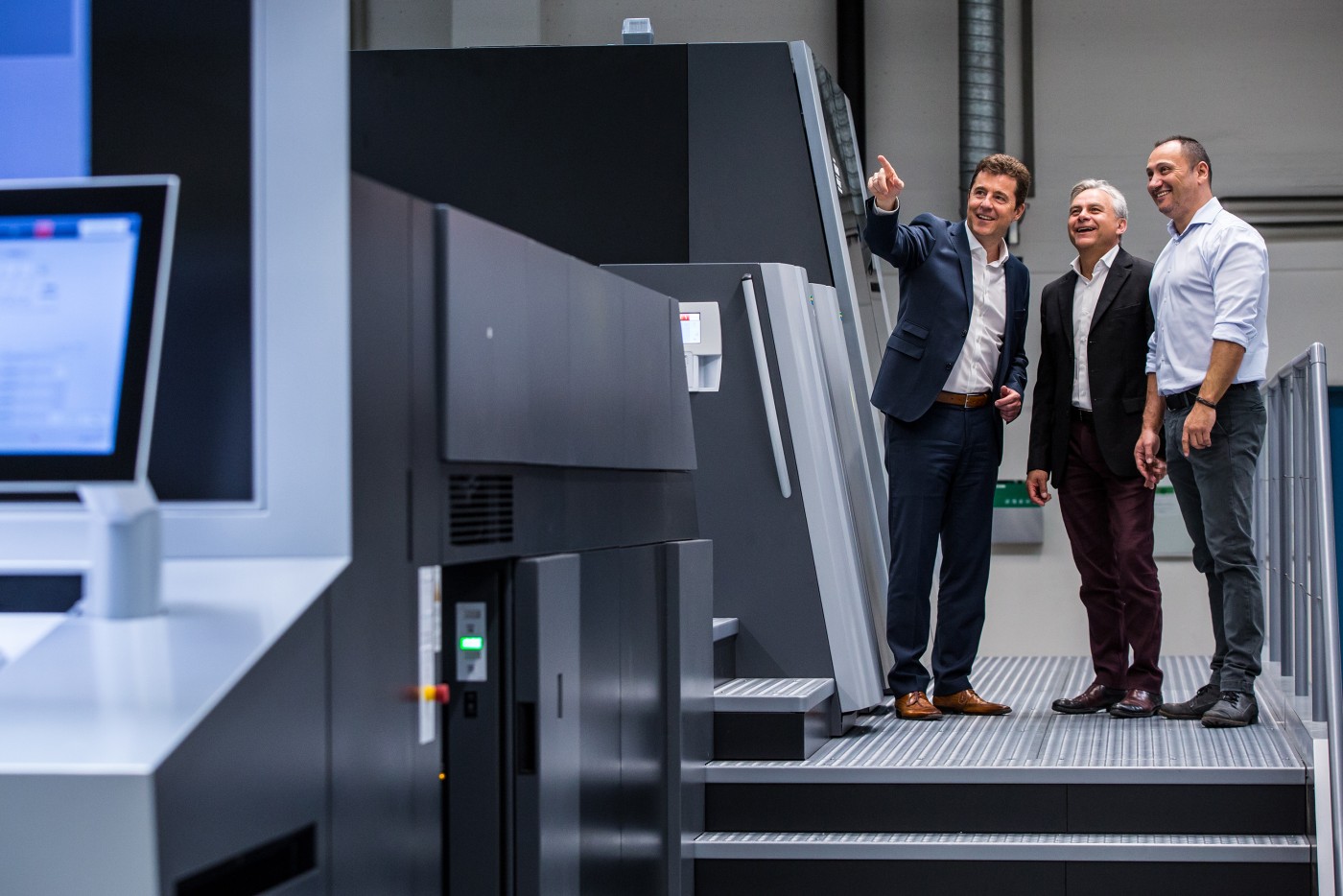

Pharmaceutical packaging specialist Rondo AG installs the Heidelberg Primefire 106 to further expand its Supply on Demand solution

Print quality and color stability of the digital printing system a decisive argument for the investment

B1 format fits perfectly into the existing production setup, with digital and offset printing complementing each other

Automated workflows, close integration of customers into the process and digital printing further shorten packaging delivery times

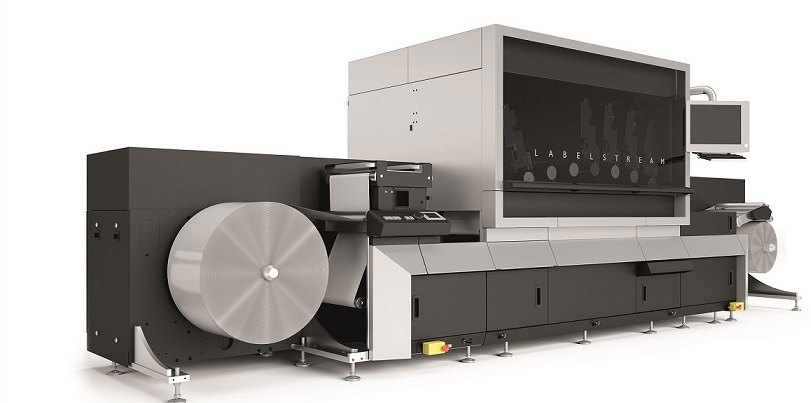

Xaar 2001+ printhead technology delivers the speed needed for new Canon digital label printer

The combination of speed, quality and reliability of the Xaar 2001+ U printhead made it the ideal choice for Canon’s entry into the digital label printing market, with the launch of its Océ LabelStream 4000 press.

Unilever takes delivery of Gebo Cermex end-of-lines

Gebo Cermex has commissioned two end-of-lines for production of shampoo and conditioner in shaped bottles at Unilever’s new personal care facility in Dubai. The new two packaging machines meet the Unilever’s requirement for a new technology that combines a modular design, ensures faster, shorter, and highly responsive production lines to reduce lead-time to market.

Olympus reaches a new high with three Nilpeter FA-4* flexo presses

Olympus Print Group, UK specialists in self-adhesive labels and large format digital print, has increased capacity and market share in wine and beverage and high-end labels, with the acquisition of three Nilpeter FA-4* flexo presses over the course of the last 18 months.

BOBST launches revolutionary Digital Inspection Table to offer superior print quality control

BOBST has unveiled its pioneering Digital Inspection Table – a novel technology designed to drive productivity and virtually remove print production errors.