The print and packaging industry is entering a profound transformation, with changing consumer behaviors and new technologies disrupting the industry. Brand owners of every size are under increasing pressure to deliver the ideal packaging blend of design, substrates and quality. For converters, new business opportunities are on the rise. The Industry 4.0 principles are entering into the packaging industry and we are at a tipping point where smart factories will become a reality. Connecting the dots between Packaging 4.0 and Industry 4.0 is of great strategic importance for converters and brand owners alike.

Sidebar

Analogue Printing

Flexible packaging: 80% cost reduction through seamless quality control inspection system

More and more brand owners are relying on the powerful impact of flexible packaging to further consolidate their shelf presence in the retail sector. But despite the high demand for innovative packaging solutions, manufacturers are facing tough competition as the demands for high-quality printed products continue to rise. To meet the increasing demands of its customers, the US packaging manufacturer Plastic Packaging Technologies relies on the 100% inline inspection system PrintSTAR from the world's leading supplier of inspection systems ISRA VISION.

Rossi EP series, “ready to use” planetary gearmotors

High quality standards, 3 year warranty, customization and wide range of executions and accessories are some of the features of the service and of the wide range of Rossi S.p.A. planetary gear reducers and gearmotors. High performance "ready to use" technologies, without compromise and without waste, combined with a flexible and dynamic service, able to satisfy all the needs in different application sectors.

New flexoprinting machine in Jatne will answer to growing demand for sustainable food packaging

The demand for flexible packaging materials is growing amid the transition towards sustainable food packaging. Walki has answered to this need by investing in a brand new flexo printing machine in its Jatne plant in Poland.

Expansion of the Customer Technology Centre

Growth market for flexible packaging

Increased world market share

Evo XD 8 combines versatility and reliability

Expansion of the Customer Technology Centre

Gallus High Performance Day 2021: First virtual event was a great success

The number of participants and the positive feedback speak for the new event format. With more than 1500 registrations the Gallus High Performance Day 2021 on the 3rd and 4th of March 2021 was a huge success. Using this new digital event format, Gallus demonstrated the highlights of digital and conventional label printing systems. In addition, expert talks informed about different topics like digital label printing with low migration inks.

Water-based gravure printing: working together for a sustainable future

High solvent use in gravure printing is perhaps the biggest hurdle to overcome in order for this sound technology to maintain its strong position longer term. With increased government regulation globally and public opinion favoring new greener technologies, the future opportunities for gravure are destined to be coupled with more sustainable manufacturing technologies aimed at making alternative greener process applications more efficient.

The story behind BOBST’s success in Asia with bestselling gravure presses

Innovation is driving the implementation of BOBST’s advanced gravure technology in emerging markets throughout India and South-east Asia. By responding to the specific requirements of these markets, BOBST has successfully established itself as a technology leader in the flexible packaging sector here

New Lithrone GX44RP/G44 advance Models Added to Lineup of Lithrone GX/G advance Series

Komori Corporation (Sumida-ku, Tokyo, Japan; Representative Director, President and CEO: Satoshi Mochida) has announced that new Lithrone GX44RP/G44 advance models have been added to the lineup of Lithrone GX/G advance series sheetfed offset presses.

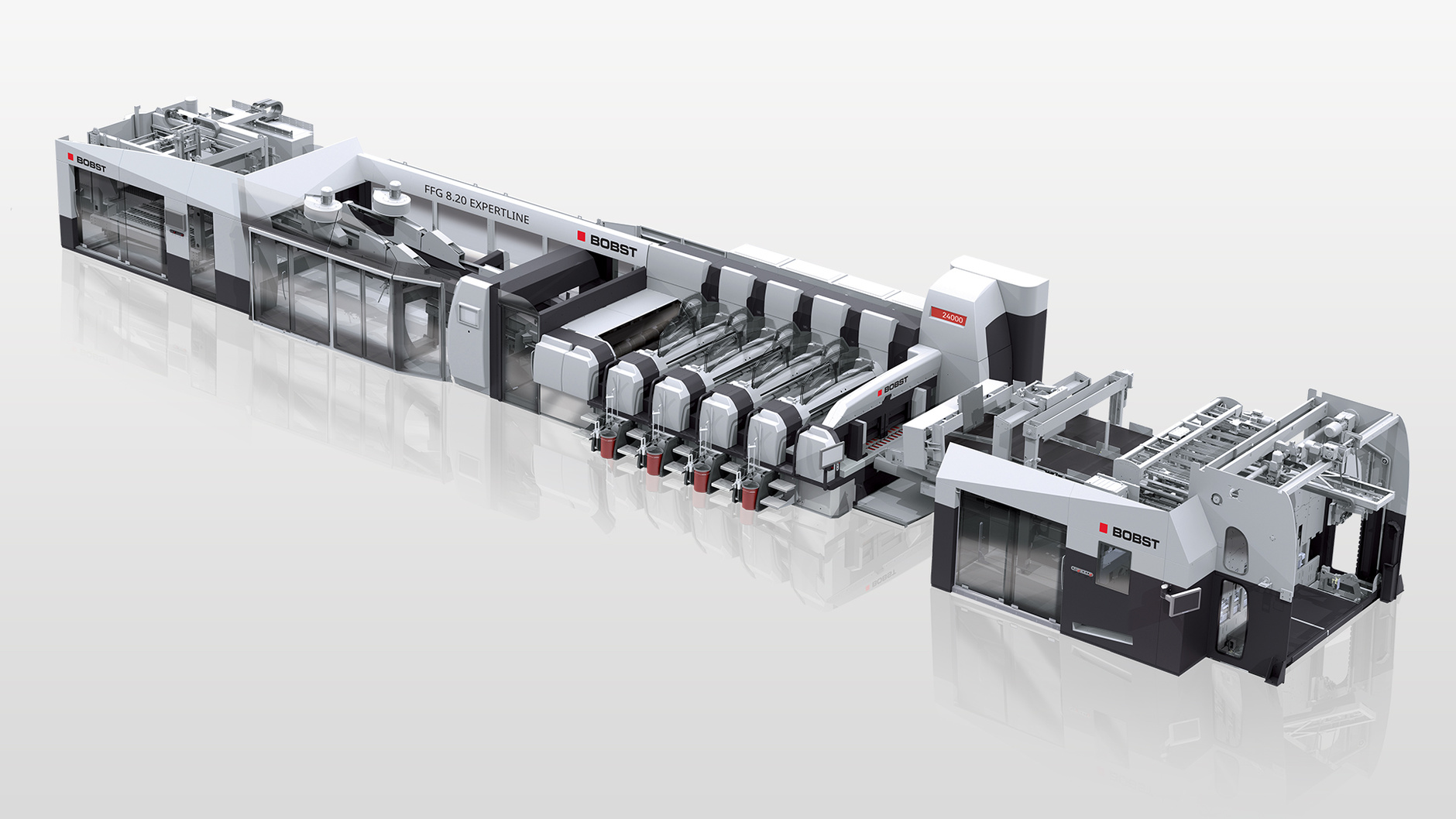

BOBST FFG 8.20 EXPERTLINE: turning e-commerce challenges into opportunities

The already booming e-commerce sector has skyrocketed even further in 2020 due to the COVID-19 pandemic, with global revenue from online sales in the second quarter of 2020 growing by an extraordinary 71% compared to the previous year.1

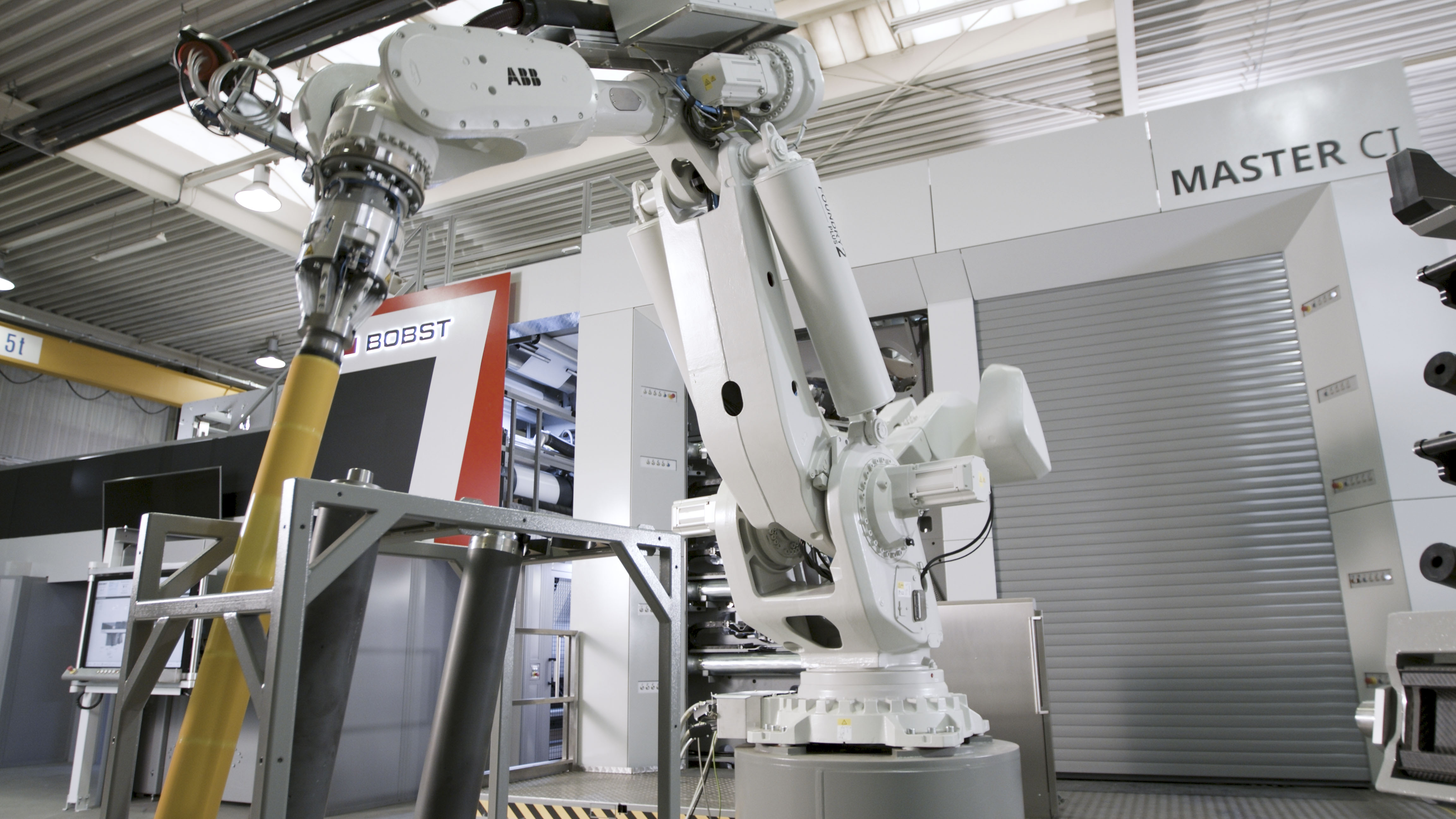

BOBST demonstrates the future of flexible packaging production at groundbreaking virtual Open House event

BOBST hosted a unique virtual event from its state-of-the-art Competence Centers in Bielefeld, Germany and San Giorgio Monferrato, Italy, which enabled attendees to see the future of flexible packaging production from the comfort of their own homes.