RAFESA, a benchmark in sustainable packaging for the perfumery, cosmetics and pharmaceutical sectors, is proud to announce it will attend PCD Paris 2025 as an exhibitor for the first time. This prestigious international event will take place on 28 and 29 January at the Paris Expo Porte de Versailles and gathers all the main stakeholders in the packaging sector.

Sidebar

Applications

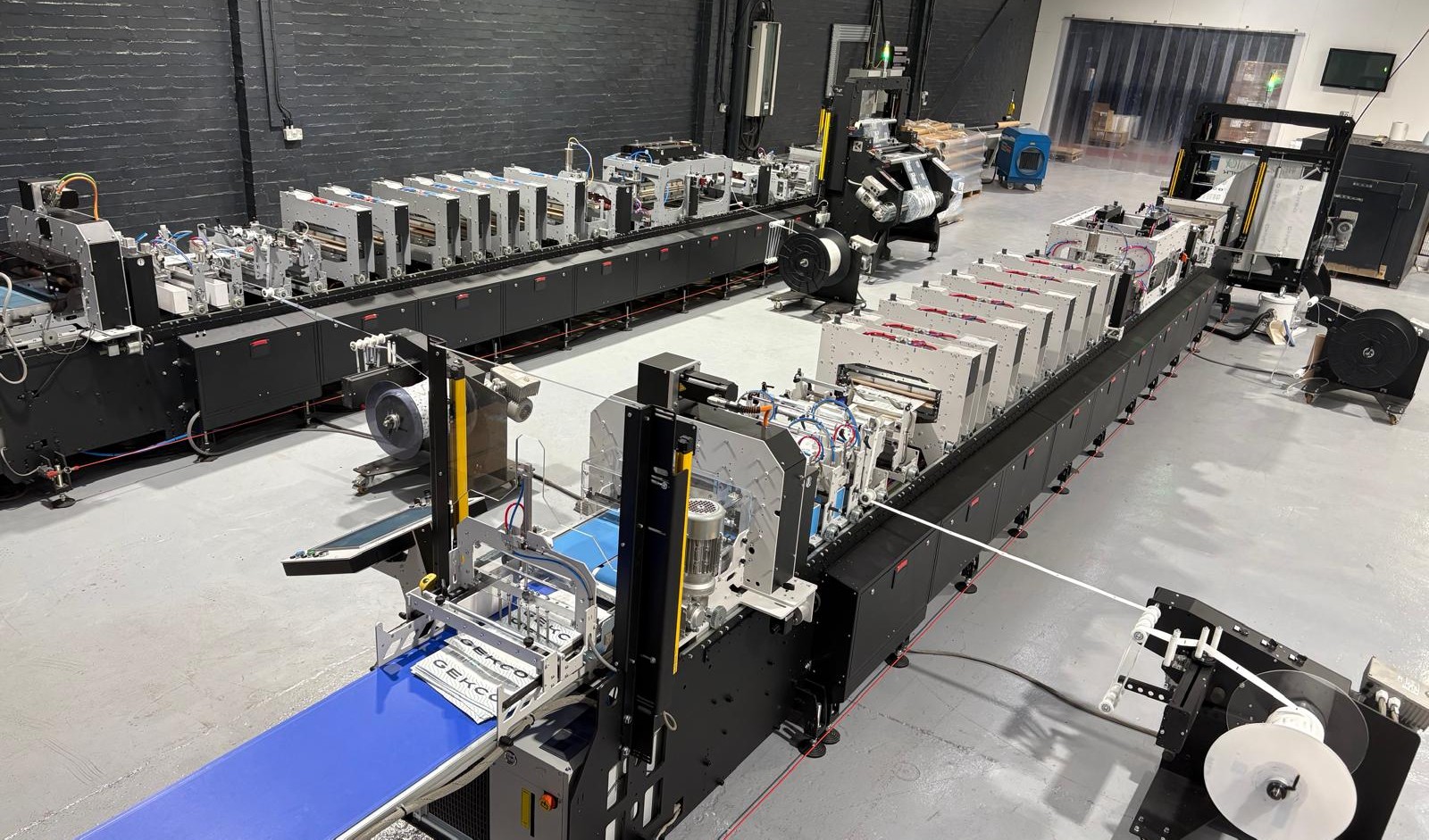

Eco Flexibles expanded product range success leads to further investment

Recyclable flexible packaging innovator, Eco Flexibles, has increased its capabilities with the installation of a second pouch machine following the significant success of its expanded product range.

Sonoco to Showcase Award-Winning Recyclable Packaging Solutions at Packaging Innovations & Empack 2025

Sonoco is pleased to announce its upcoming presence at Packaging Innovations & Empack 2025 in Birmingham, UK, from 21 to 22 February 2025 (Stand P38). At the event, Sonoco will showcase its latest sustainable packaging solutions, as well as its award-winning recyclable products.

Doro Packaging at Paris Packaging Week 2025: A Landmark Innovation for Sisley

Doro Packaging and Sisley redefine luxury box inserts with a 100% cardboard solution

3-D Printed Packaging

KnurlPack is our core technology process. Patented as 3-D Printed Packaging (Packaging Process), our innovation in packaging provides disruptive opportunities for packaging of locally crafted or manufactured products in 3-D printed packages. Packaging can be printed partly or fully around products and goods, customized

Sonoco to Showcase Versatile Packaging and Contract Manufacturing Portfolio at Pharmapack 2025

Sonoco’s TEQ, Plastics, and Consumer divisions will display their latest packaging innovations, as they exhibit at Pharmapack 2025 for the first time

VTT launches new origami packaging technology to create sustainable lightweight, durable, and eye-catching alternatives to conventional protective packing materials

VTT Technical Research Centre of Finland, in collaboration with Aalto University and Finnish industrial partners, has developed a new technology for shaping cardboard in a unique continuous process to create reel-to-reel origami-inspired structures for fibre-based packaging materials. The origami folds have the capacity to yield entirely new properties from cardboard.

UFlex’s FlexiTubes to Showcase Sustainable Products for the Beauty Industry at COSMOPROF INDIA 2024

FlexiTubes, the packaging tube division of UFlex— India’s largest multinational flexible packaging and solutions company—will showcase its innovative and sustainable tube offerings tailored for the beauty industry at COSMOPROF INDIA 2024. This leading B2B event focused on the thriving beauty industry is scheduled to take place in Mumbai, India, from December 5-7, 2024.

New in the USA: electric Allrounder processes solid silicone rubber

• Spotlight: reliable processing of solid silicone rubber (HCR) on electric Allrounder 470 A

• Focus: target groups are the medical, automotive and aerospace industries

• On trend: surging demand for digital products and services

All You Need is airless

The new luxury skincare range by celebrated Dr. Gloria Mang is made and decorated at Quadpack’s German facilities

Shanghai World of Packaging (swop) 2024 Offers Unique View of UNITED CAPS’ Latest Sustainable Packaging

UNITED CAPS’ UNITED WE STAND and CLOSE TO YOU initiatives demonstrate its clear differentiation in the caps and closures business, with the latest solutions on display in Booth W3B10 at the International Pavilion.