The globally operating diemaker Marbach is known on the market for its innovative solutions for packaging production. In the corrugated board sector, one of the latest Marbach technologies is the DZL|plateXL, a zone levelling solution for large format die-cutting machines. This ensures significantly reduced make-ready times.

Sidebar

Consumables

Lecta Introduces its Termax Products TC20X and TC20XB

Two new high-quality phenol-free thermal products

DuPont celebrates 50 years of the Cyrel brand, emphasizing its commitment to innovation for the next generation of flexographic printing

The Cyrel® brand's 50th Anniversary celebration will take place throughout 2024, as Cyrel® heralds a new era of flexographic printing innovation with customers and industry partners alike.

Fujifilm launches 46kUV Inkjet Printbar System for high-speed labels and packaging production

Fujifilm announces the launch of its 46kUV Inkjet Printbar System, a new, integrated print solution for industrial production operations across a wide range of labels and packaging materials. The 46kUV Inkjet Printbar System features a drop-on-demand design to streamline workflow with fast, industry-leading printing speeds of up to 150 metres per minute.

Sun Chemical Implements Freight Surcharges in Light of Red Sea Crisis

Sun Chemical will implement selected freight surcharges impacted by the Red Sea crisis globally.

Kongskilde Industries launches new Compact Unit

Kongskilde Industries introduces the CUB Compact Unit with Bag. This revolutionary machine-side waste collection unit redefines waste handling for production lines involved in label converting, film extrusion, coating & lamination, slitting & rewinding, printing, or packaging production.

DREWSEN SPEZIALPAPIERE restarts sales of new PROSEAL Heat Sealable Paper for packaging of non-food stuff and dry foods

Sustainability and environmentally friendly solutions are increasingly influencing our everyday lives. Brand owners, consumers and the European Parliament are demanding alternatives to plastic.

hubergroup Chemicals presents its portfolio at PaintIndia

Designed in Germany – Made in India

hubergroup Chemicals is one of the largest manufacturers in the chemicals sector

Sandon Global heads into its 20th year of anilox excellence after a record year in 2023

Sandon Global, the British anilox manufacturer headquartered in Runcorn, Cheshire, has reported record sales in 2023 as it embarks upon the new year with plans to build on the company’s success and mark 20 years of anilox excellence.

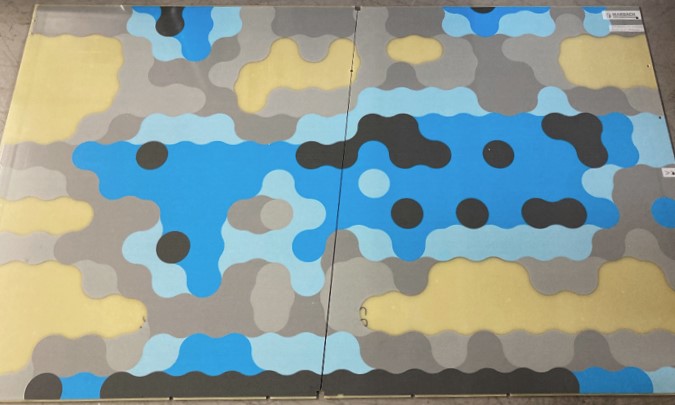

The masterstrip|plate from Marbach for best stripping performance

Over the decades, the globally operating diemaker Marbach has developed numerous solutions that provide the user with more performance in the production of packaging. One of these innovations is the masterstrip|plate.

The masterstrip|plate is a special upper stripping tool - in combination with the marbastrip technology developed by Marbach – that ensures a smooth and safe stripping process.

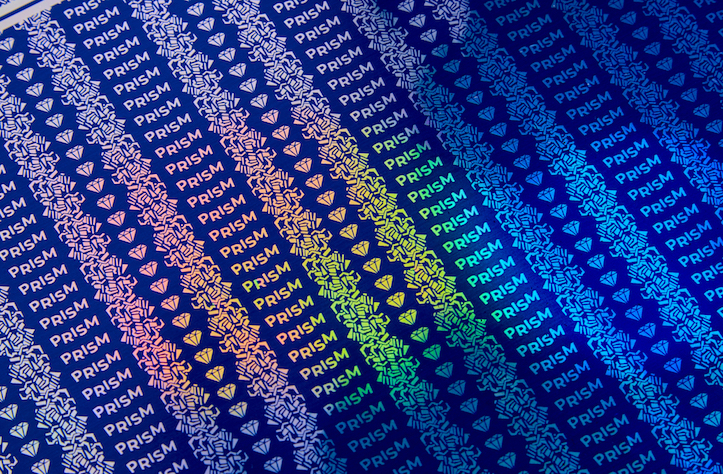

Filtrona Tapes' Prism range to light up Packaging Innovations

Leading tear tape solutions provider Filtrona Tapes will aim to shed new light on flexible packaging and prove why Supastrip® Prism is the answer when it lands at the UK's flagship packaging exhibition next month.