UV LED systems for the electronics manufacturing adhesives curing

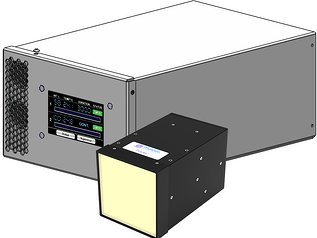

Phoseon Technology, the leader in UV LED curing solutions, today introduced the release of the FireJet™ FJ801 area curing solution, now with a touch controller. The intuitive user interface of the controller’s touchscreen allows for easy operation. With no knobs or buttons and other moving part on the front, the controller can be stored and transported more easily. The system targets electronics manufacturing, adhesives cure and lab material/substrate curing.

“The FJ801 light source continues to have excellent uniformity and reliability, now with an easy-to-use controller, displaying critical process safety information including lamp temperature and accumulated time that the LED lamp has been turned on.” Stated Rui Zhou, Technical Marketing Engineer. "The new controller is backward compatible FJ800 lamp too.”

The FJ801 and FJ800 light sources are designed primarily for production lines which requires area curing such as micro speakers and camera modules manufacturing. Starting from a base curing area of 100mm x 100mm, these modular products can scale in both directions, to provide contiguous, uniform UV output. The light source is available in 365nm/385nm/395nm/405nm wavelengths. The light source also offers process stability with Phoseon’s patented TargetCure™ technology that provides users with precise and predictable UV output.

www.phoseon.com