Labelling of controllers and hydraulic pumps with hinged paint protection label

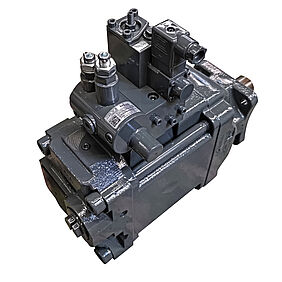

If components with an individual marking are painted, the marking must be protected from the paint so that it is legible again after the painting process. Schreiner ProTech has a label in its portfolio where the paint protection label is attached to the identification label. After marking with the 2D code, the hinged paint protection label is applied by folding it over. The company InLine Hydraulik GmbH relies on exactly this solution for the marking of controllers and hydraulic pumps in the painting process.

Up to now, InLine Hydraulik has used metal nameplates at the end of production for marking. The integration of digital information and the storage or tracing was not possible automatically. Schreiner ProTech's new hinged paint protection label is printed with a 2D code on site and manually applied to the pumps and the controller early in the production process. After painting, the paint protection is removed, ensuring readability. This new solution made it possible to introduce the 2D code. This enabled InLine Hydraulik to optimize the production process and make it safer. Automated traceability is now possible at any time.

Schreiner ProTech's paint protection solution additionally allows the combination of a removable paint protection label with a durable laminate to permanently protect the underlying type plate from mechanical stress. After the drying process of the applied paint layers, the protective label is removed by means of a peel-off tab. This ensures easy handling even when wearing work gloves. The paint protection itself is slightly smaller than the identification label. This means that after removal of the paint protection film, the label is embedded in the paint and is thus permanently protected.

www.schreiner-group.com