Dispatch packaging with safety closure

The sustainable, digitally printed shipping packaging with the innovative THIMM secureLock closure technology is the result of the packaging development with the Swiss start-up yamo. In addition to the first-class printing result with ThimmColor digital, the packaging provides optimum product protection and is also particularly suitable for orders in the food shipping sector.

Sidebar

Flint Group Packaging Inks & Flexographic participate in Soma on-line webinar

Flint Group collaborates with Soma and Marvaco to deliver groundbreaking global print technology weinar to 1,000 attendees

Flint Group has collaborated with key industry partners to deliver a comprehensive webinar on the latest technology available to deliver successful extended gamut printing (EGP).

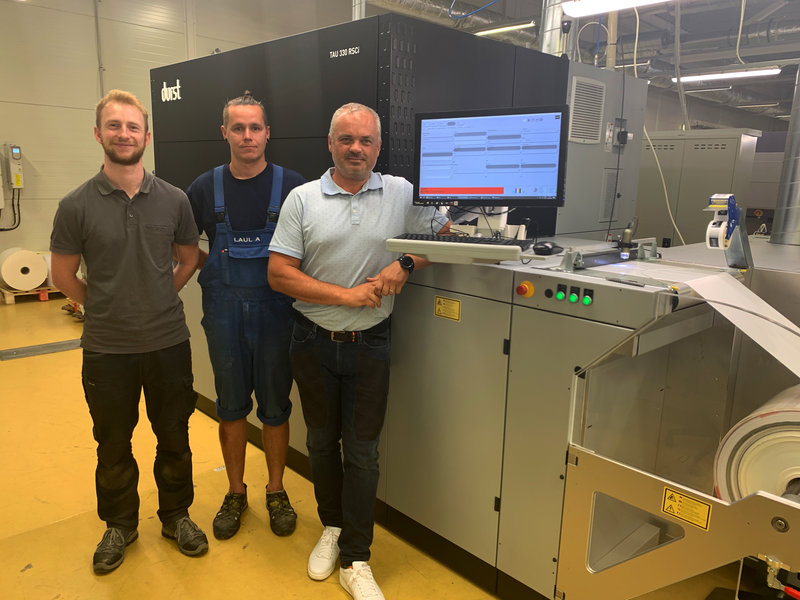

LabelPrint OÜ chooses Durst Tau RSCi for flexo switch to digital

Durst has announced the official start of beta testing of its new Tau RSCi label press at label converter LabelPrint OÜ. The new single-pass UV inkjet label press, which was announced at Labelexpo Brussels last year, was installed at its headquarters in Tallinn, Estonia, in July 2020.

Preview of Domino’s New Business Model for Corrugated Box Production

As the countdown approaches to the virtual launch of Domino Digital Printing Solutions’ first step into the digital corrugated printing space on 16 June, Domino has released a short teaser video giving you a sneak preview of their single pass Domino X630i digital ink jet press. Designed for everyday corrugated production, this highly automated ink jet printing solution utilises a new aqueous ink set based on novel water-based ink technology.

Rospil’s total confidence in Durst leads to Tau 330 RSC E investment to capture new markets

Etiquetas Rospil has taken the next step on its digital transformation by capturing new markets with an investment in a Tau 330 RSC E from Durst, manufacturer of advanced digital printing and production technologies. Increasing numbers of its own customers are explicitly demanding that their labels are produced on the single-pass inkjet press.

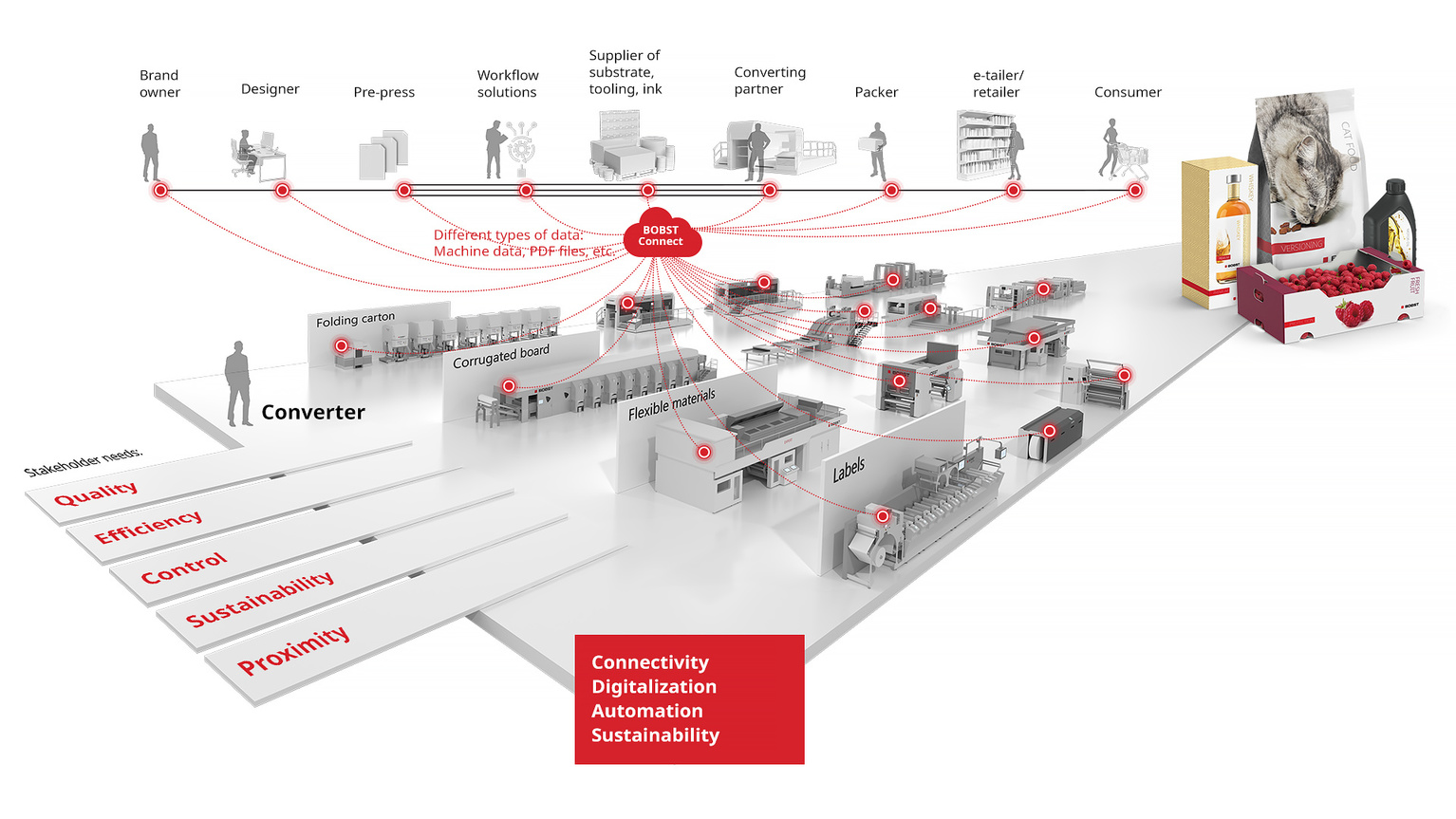

BOBST’s new industry vision is shaping the future of the packaging world

A profound transformation to help converters to better answer Brand Owners’ new and critical requirements.

The BOBST vision is shaping a new reality where connectivity, digitalization, automation and sustainability are the cornerstones of packaging production. BOBST continues to deliver best-in-class machines, and is now adding intelligence, software capabilities and cloud-based platforms, to make packaging production better than ever.

BOBST unveils a new vision for the packaging industry and launches a new range of machines and solutions

The BOBST vision is shaping a new reality where connectivity, digitalization, automation and sustainability are the cornerstones of packaging production. BOBST continues to deliver best-in-class machines, and is now adding intelligence, software capabilities and cloud-based platforms, to make packaging production better than ever.

Production Interface minimizes case and pallet labeling downtime and rework

The 2200 Production Interface launched today reduces the risk of rework and recalls by minimizing the scope for operator error, since label data and formats can be more easily controlled. Downtime is reduced by the ability to preview and adjust labels digitally. It is also improved by a large intuitive touchscreen which helps operators work more quickly.

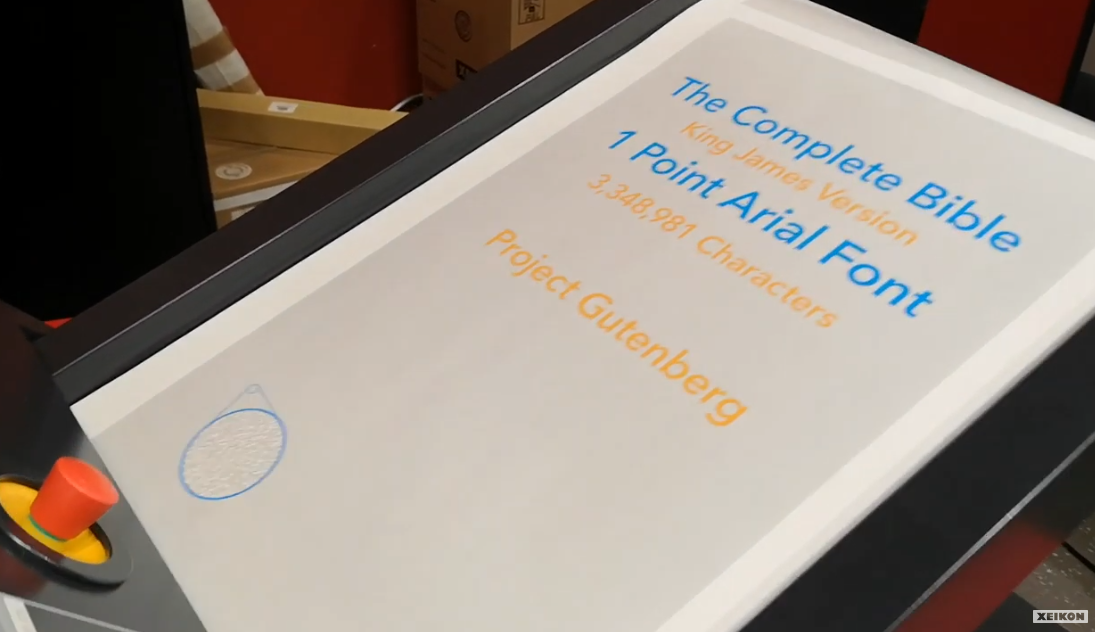

Xeikon: The whole Bible on one page

Xeikon’s imaging technology is ultra-sharp and Xeikon’s dry toner is ultra-small.

BGR Label adds second Truepress Jet L350UV inkjet to its production floor

BGR Label near Cincinnati, Ohio converted 95% of its 4-color process label work to its first SCREEN L350UV digital inkjet press resulting in so much additional business it recently installed a second machine, the latest generation L350UV+.