Label production has gone mainstream, with more than a third of the total value already created entirely digitally or hybrid. The move towards digitalisation is being fuelled by brands and retailers who expect label production to be more agile and able to respond quickly to rapidly changing demand patterns. Konica Minolta presents the trends and drivers in label printing in the coming year.

Sidebar

Help and Learning

Are Paper Substrates The Future Of Flexographic Label Printing?

By David Lee, Focus Label

For many years, paper became almost a dirty word in the world of commercial printing. Paper labels and packaging were seen as old fashioned, inflexible, difficult to recycle, unsustainable to produce (due to exploitative timber farming practices), and heavy in ink consumption.

Packaging for beverages is growing more sustainable

PET or glass bottle, aluminium can, beverage carton or maybe even a paper bottle, single use or multiple use – there is a huge range of choices for packaging beverages. But which is the most sustainable? The focus has increasingly been placed on ecological aspects over the last few years in this sector. And not only for packaging material: these aspects have also become important for filling and actual packaging processes.

Inflation And Volatility Boost the Business Case for Automation in Manufacturing

The world is facing the highest inflation rates in 40 years, and pundits are talking of a possible recession in the coming months.

Is It Worth It? The Six Big Risks of ‘Compatible’ Inks and Consumables

When faced with increasing production costs, manufacturers may be tempted to save money by buying low-cost, unbranded, or white-label printer inks and consumables marketed as ‘compatible’ by third-party ink providers. Still, there are very good reasons why this should be avoided.

Eliminating and Capturing Printing Errors – Prevention vs Cure

The last few years have come with many business interruptions, including the global pandemic, supply chain problems, and a reduced workforce all causing havoc for businesses across the world. Unfortunately, these disruptions to normal business practices have driven some manufacturers to make compromises in order to meet deadlines and therefore resulted in production errors being identified at a late stage when the maximum cost has already been invested.

Pharmaceutical packaging: Safety is what counts

The demand for pharmaceutical products is increasing worldwide, with more and more medications being launched onto the market in ever shorter periods of time. Last year alone, turnover in the German pharmaceutical market – the largest in Europe and the fourth largest worldwide – was around 53.6 billion euros. According to Statista, the volume has more than doubled in the last fifteen years and almost 100 billion counting units, i.e. tablets, sachets, injections, etc., were sold at last count. They all have to be packaged hygienically and safely, meeting strict legal requirements. This places high demands on packaging materials, filling processes and packaging machines.

AWA publishes the first Sustainability Report on Label and Product Decoration Market.

As the label volumes continue to grow year on year, its growth prospects continue to become increasingly influenced by increasing consumer pressure in regard to environmental concerns, legislation, and industry guidelines for all level of global value chains.

Medium-sized packaging hit hardest by inflation as customers turn to bulk buying or premiumization to get more bang for their buck, says GlobalData

Products with medium-sized packaging will be hit the hardest by changes to consumer shopping amid rising inflation, says GlobalData, as the leading data and analytics company notes an emerging polarization in the market.

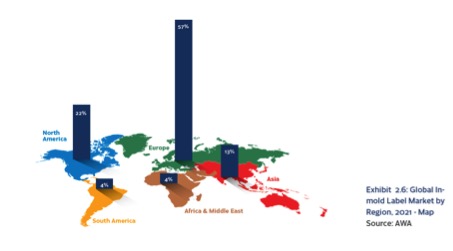

In-mold Label product decoration: The new 2022 AWA publication reports growth of the market

In-mold labeling is a technology that has a typical application in the decoration of rigid and semi-rigid container – usually for FMCG products. It exhibits the most complex structure of all label formats, involving close cooperation and integration of all the players along the value chain to achieve the desired levels of quality in product decoration.

Fresh Figures: New Ceresana Report on the European Food Packaging Market

Defying the trend, food retail revenues increased in many countries during the pandemic, as restaurants were closed and consumers had plenty of time to cook for themselves.